Here are a couple renderings of the front...

Tuesday, December 6, 2011

SECTIONS

Here are some updated building sections. You can see in the overall section cut through the dining space how the eyebrow windows work. I am still playing with the section and the support of the windows and the roof in this area. I am showing beams, but I think I will switch and use girder trusses to support the opening since there is very little load involved. I will probably still have to keep the beams below the window, but these are easy to pick up and are no big deal since they can sit on the exterior walls and will not affect the basement space.

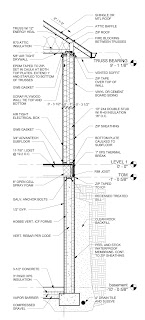

This detailed section shows how the walls are constructed, tied into the floor/foundation and roof structure. Buildings have 6 sides. Most people only consider the walls and roof...sometimes. Basement walls and floors are also important parts to consider. The building has to work as a whole to keep in the heat or cool, and allow you to control the air in and out.

This starts with the basement slab.

Most people do not like basement floors without carpet or some sort of covering. The main reason is because it is cold. That is a result of most basement slabs are uninsulated. An insulated slab allows you to thermally break the colder ground below and reduce the thermal transfer from the ground to the slab. By increasing the thermal layer, you can further isolate the slab. The mass effect of the slab will absorb heat to the exposed temperature. If it is exposed to the air temperature and it does not have the cold of the earth below it, the slab will start to take on the air temp, approximately 70 degrees. The slab will still feel cool to walk on since anything below body temp feels cool to the touch, however the slab will not be 50 degrees, or similar to the earths temp. Some people add radiant heat tubes to the concrete which will produce a warm, even heat out of the slab. However this sort of install is not necessary for a house of this thermal level, therefore not a wise investment for me.

I do plan on leaving the slab exposed in the family area and going with a darker stained concrete. This will produce a very durable floor that can not be damaged in the event of water leaks.

The floor sits on 3" of XPS insulation, achieving an r-15 below the slab. Below the foam will be a poly membrane, sealed and taped to prevent moisture penetration from the ground. Below the plastic will be 4-6" of clean, compressed gravel to help prevent moisture from getting to the slab.

Moving to the basement wall, I am using Hobbs vertical ICF forms for at least the below grade walls. Check out their links on the PRODUCTS link to the right. These straight forms have a higher average r value then most eps forms (around r-27-30) due to the design that also doubles and requires less concrete. However less concrete does not equal sub par foundation. It is an engineered system, using concrete and steel right where it needs it.

With the under slab foam touching the ICF form which goes to the footer, this allows a continuous thermal break between the ground and slab, and also between the slab and the exterior walls. Thermal breaks like this are important in the overall design of a home like this.

It is still completely undecided, but I will probably go with a peel and stick style water barrier on the exterior of the basement walls. This typically stops just below grade, but in this case I want to run it all the way up to the top of the form and tape it off to the ZIP sheathing. This helps continue the air barrier from roof all the way down into the ground, and helps take care of notoriously leaky spots right around the mud sills and floor framing area.

Speaking of this area, since it is very leaky area with awkward areas to insulate, penetrations from electrical and other services, I will seal it from the exterior, but also use 6" of open cell spray foam to seal this area off and expand around the odd shapes of the floor joists. The mudstill itself will be recessed into the ICF to allow that thermal break in the wood, and sill seal will be applied in a double layer between the mud sill and the concrete prior to being bolted down.

To continue the thermal break at the floor framing, the 11-7/8" floor joists will rest on the center of the mud sill. The rim board will then be caulked to the joists prior to being nailed on. The rim board will also be set in a bed of caulk to the mud sill. After this is nailed off, a 1" layer of XPS foam will be ripped to the exact with of the rim board and foamed and taped in place to the rim board. The exterior 2x4 wall will be set flush with the outer face of the foam allowing the ZIP sheathing to run continuous past the 2x4 wall, over the foam and nail off. This achieves a super tight connection of the walls to the foundation, and addressing a very leak prone area of the house often ignored. As mentioned above, the ZIP will then be taped off to the peel and stick membrane to create an air tight seal.

Moving up to the walls.

After hours upon hours upon hours of research, I have settled on the double stud wall as the wall of choice. I have explored about everything up there from typical 2x6 with exterior foam and blown, 2x4 walls with all the foam on the exterior, SIPs, full ICF

The 10" thick wall started out as a 12" thick wall. However after energy modeling and calculations, it was determined that a 10" wall will perform similar but at a higher reduced cost. Cost savings is not just in 2" of insulation, but it saves floor space. The downside of double stud is creates a thick wall, so to get similar floor space, you need to expand the foundation which adds cost. The 2" wall difference will perform almost the same (took only about 500 btu off my load calc) but saved a couple thousand dollars in cost due to savings in foundation and insulation. It also will have some savings in property taxes since they are measured from the exterior shell. I can still hit an r-40 with blown fiberglass in this wall assembly. Due to the lack of thermal bridges, the wall will perform pretty close to r-40, very unlike a typical 2x6 wood framed wall.

The 10" thick walls will have the floor plates set in caulk prior to them being tipped up. This will seal the plates to the subfloor (which is sealed to the floor structure and rim board with the construction adhesive). ZIP sheathing runs continuous to provide the exterior air barrier. The proprietary tape seals it off. Homes can achieve very tight levels using ZIP sheathing. This system costs about $5 more per sheet, plus the cost of the tape, which adds approx $2 more per sheet. However it does not require a building wrap, so savings is had there. Plus the install is faster since you do not need to install the building wrap. It also eliminates the repairing of the wind ripped wraps. In the end it works out to only be about a $500-800 upgrade. Small price for the air sealing and time savings.

Window openings are also taped off continuously from the exterior to the interior. The window in then set in caulk and an additional layer of tape is applied over the flange. Low expanding foam fills the interior rough opening gap, and then the window is taped off again to the interior face of the studs. Opening cracks around windows are very leak prone areas, so attention to sealing these areas are critical.

1/2" gyp board will be installed on the interior stud wall. I will double up my air barrier and use air tight drywall techniques. This requires the gyp be sealed at all exterior locations. The cleanest way of doing this is installing gaskets to the top and bottom plates, around the windows, and at intersections of interior walls prior to the gpy being installed. Air tight electrical boxes will be used in the exterior walls and the drywall caulked to the boxes to prevent air leak in these locations. However I will only use the boxes are required, and will attempt to put as little electrical on the exterior walls as possible.

Some argue this belt and suspender methods are not needed to have two air barriers, but its not much added cost and can only make it a tighter home.

Since my air barrier is on the exterior plane, it needs to continue up my roof. Since I am using a vented roof assembly with a energy heal truss, it is not possible to maintain an exterior air barrier plane.

Because of this, I need to transfer my air barrier from the exterior to the interior over the top plate. This will be done using air tight drywall on the ceiling, caulked and gasketed off to the top plate. The top plates will be caulked together. A piece of EPDM will be set in caulk and taped across the top plates to seal off the wall and help to transfer the air barrier from the exterior to the interior. The plan is to leave about 1' hanging to the interior side. After the trusses are up, the EPDM will be stapled to the underside of the truss. The gyp will press against this creating a gasketed seal. There will also be a drywall gasket applied to the top plate further enhancing this seal. ZIP tape will wrap up and over the plate to seal that crack off. Fire blocking will be installed in 2' pieces with a 1 1/2" gap in between to set the trusses into. This will allow us to easily set the trusses without messing with aligning a truss. Rather we can use a laser and align simple blocks making truss erection much quicker.

All penetrations in the ceiling plane will be boxed out from above, caulked and taped to the gyp and trusses.

From this point up, it is pretty typical. Simple standard wood trusses, sheathing, and roofing choice yet to be determined. We are considering metal, but we will see how things shake out.

The ceiling plane would then be finished off with r60-70 blown in fiberglass insulation.

This detailed section shows how the walls are constructed, tied into the floor/foundation and roof structure. Buildings have 6 sides. Most people only consider the walls and roof...sometimes. Basement walls and floors are also important parts to consider. The building has to work as a whole to keep in the heat or cool, and allow you to control the air in and out.

This starts with the basement slab.

Most people do not like basement floors without carpet or some sort of covering. The main reason is because it is cold. That is a result of most basement slabs are uninsulated. An insulated slab allows you to thermally break the colder ground below and reduce the thermal transfer from the ground to the slab. By increasing the thermal layer, you can further isolate the slab. The mass effect of the slab will absorb heat to the exposed temperature. If it is exposed to the air temperature and it does not have the cold of the earth below it, the slab will start to take on the air temp, approximately 70 degrees. The slab will still feel cool to walk on since anything below body temp feels cool to the touch, however the slab will not be 50 degrees, or similar to the earths temp. Some people add radiant heat tubes to the concrete which will produce a warm, even heat out of the slab. However this sort of install is not necessary for a house of this thermal level, therefore not a wise investment for me.

I do plan on leaving the slab exposed in the family area and going with a darker stained concrete. This will produce a very durable floor that can not be damaged in the event of water leaks.

The floor sits on 3" of XPS insulation, achieving an r-15 below the slab. Below the foam will be a poly membrane, sealed and taped to prevent moisture penetration from the ground. Below the plastic will be 4-6" of clean, compressed gravel to help prevent moisture from getting to the slab.

Moving to the basement wall, I am using Hobbs vertical ICF forms for at least the below grade walls. Check out their links on the PRODUCTS link to the right. These straight forms have a higher average r value then most eps forms (around r-27-30) due to the design that also doubles and requires less concrete. However less concrete does not equal sub par foundation. It is an engineered system, using concrete and steel right where it needs it.

With the under slab foam touching the ICF form which goes to the footer, this allows a continuous thermal break between the ground and slab, and also between the slab and the exterior walls. Thermal breaks like this are important in the overall design of a home like this.

It is still completely undecided, but I will probably go with a peel and stick style water barrier on the exterior of the basement walls. This typically stops just below grade, but in this case I want to run it all the way up to the top of the form and tape it off to the ZIP sheathing. This helps continue the air barrier from roof all the way down into the ground, and helps take care of notoriously leaky spots right around the mud sills and floor framing area.

Speaking of this area, since it is very leaky area with awkward areas to insulate, penetrations from electrical and other services, I will seal it from the exterior, but also use 6" of open cell spray foam to seal this area off and expand around the odd shapes of the floor joists. The mudstill itself will be recessed into the ICF to allow that thermal break in the wood, and sill seal will be applied in a double layer between the mud sill and the concrete prior to being bolted down.

To continue the thermal break at the floor framing, the 11-7/8" floor joists will rest on the center of the mud sill. The rim board will then be caulked to the joists prior to being nailed on. The rim board will also be set in a bed of caulk to the mud sill. After this is nailed off, a 1" layer of XPS foam will be ripped to the exact with of the rim board and foamed and taped in place to the rim board. The exterior 2x4 wall will be set flush with the outer face of the foam allowing the ZIP sheathing to run continuous past the 2x4 wall, over the foam and nail off. This achieves a super tight connection of the walls to the foundation, and addressing a very leak prone area of the house often ignored. As mentioned above, the ZIP will then be taped off to the peel and stick membrane to create an air tight seal.

Moving up to the walls.

After hours upon hours upon hours of research, I have settled on the double stud wall as the wall of choice. I have explored about everything up there from typical 2x6 with exterior foam and blown, 2x4 walls with all the foam on the exterior, SIPs, full ICF

The 10" thick wall started out as a 12" thick wall. However after energy modeling and calculations, it was determined that a 10" wall will perform similar but at a higher reduced cost. Cost savings is not just in 2" of insulation, but it saves floor space. The downside of double stud is creates a thick wall, so to get similar floor space, you need to expand the foundation which adds cost. The 2" wall difference will perform almost the same (took only about 500 btu off my load calc) but saved a couple thousand dollars in cost due to savings in foundation and insulation. It also will have some savings in property taxes since they are measured from the exterior shell. I can still hit an r-40 with blown fiberglass in this wall assembly. Due to the lack of thermal bridges, the wall will perform pretty close to r-40, very unlike a typical 2x6 wood framed wall.

The 10" thick walls will have the floor plates set in caulk prior to them being tipped up. This will seal the plates to the subfloor (which is sealed to the floor structure and rim board with the construction adhesive). ZIP sheathing runs continuous to provide the exterior air barrier. The proprietary tape seals it off. Homes can achieve very tight levels using ZIP sheathing. This system costs about $5 more per sheet, plus the cost of the tape, which adds approx $2 more per sheet. However it does not require a building wrap, so savings is had there. Plus the install is faster since you do not need to install the building wrap. It also eliminates the repairing of the wind ripped wraps. In the end it works out to only be about a $500-800 upgrade. Small price for the air sealing and time savings.

Window openings are also taped off continuously from the exterior to the interior. The window in then set in caulk and an additional layer of tape is applied over the flange. Low expanding foam fills the interior rough opening gap, and then the window is taped off again to the interior face of the studs. Opening cracks around windows are very leak prone areas, so attention to sealing these areas are critical.

1/2" gyp board will be installed on the interior stud wall. I will double up my air barrier and use air tight drywall techniques. This requires the gyp be sealed at all exterior locations. The cleanest way of doing this is installing gaskets to the top and bottom plates, around the windows, and at intersections of interior walls prior to the gpy being installed. Air tight electrical boxes will be used in the exterior walls and the drywall caulked to the boxes to prevent air leak in these locations. However I will only use the boxes are required, and will attempt to put as little electrical on the exterior walls as possible.

Some argue this belt and suspender methods are not needed to have two air barriers, but its not much added cost and can only make it a tighter home.

Since my air barrier is on the exterior plane, it needs to continue up my roof. Since I am using a vented roof assembly with a energy heal truss, it is not possible to maintain an exterior air barrier plane.

Because of this, I need to transfer my air barrier from the exterior to the interior over the top plate. This will be done using air tight drywall on the ceiling, caulked and gasketed off to the top plate. The top plates will be caulked together. A piece of EPDM will be set in caulk and taped across the top plates to seal off the wall and help to transfer the air barrier from the exterior to the interior. The plan is to leave about 1' hanging to the interior side. After the trusses are up, the EPDM will be stapled to the underside of the truss. The gyp will press against this creating a gasketed seal. There will also be a drywall gasket applied to the top plate further enhancing this seal. ZIP tape will wrap up and over the plate to seal that crack off. Fire blocking will be installed in 2' pieces with a 1 1/2" gap in between to set the trusses into. This will allow us to easily set the trusses without messing with aligning a truss. Rather we can use a laser and align simple blocks making truss erection much quicker.

All penetrations in the ceiling plane will be boxed out from above, caulked and taped to the gyp and trusses.

From this point up, it is pretty typical. Simple standard wood trusses, sheathing, and roofing choice yet to be determined. We are considering metal, but we will see how things shake out.

The ceiling plane would then be finished off with r60-70 blown in fiberglass insulation.

REVISED FRONT!

Well since the last posting, I have redesigned a completely new house and concept. We looked at a 2 story option and worked up a design. However after more talking and thinking about it...we decided to scrap the 2 story and stick with the single story. It will be easier to build, safer to build, and we like the functionality of single level.

However we also looked at a more traditional craftsman style and I went to the drawing board to try and make it not so text book. I admit, it is still a basic home with simple craftsman inspired details, but lets not forget efficient homes are not mean to be complex. They are meant to be fairly simple to keep the details simple. This sort of a home lends itself to that. We also feel, in the area, it is more fitting then the other designs we have looked at.

By playing with the color scheme, I was able to "modernize" the typical green and brown inspired craftsman homes. I am proposing using 2 tone blue-gray siding and white trim. However I am using a charcoal colored fascia, soffit, and gutters, as well as paint color matched decorative post gable details.

It uses a simple truss roof with hipped sides. The rear is a simple slope with no other detailing for easy construction and cost savings. The eyebrow set of 3 windows is functional casting additional light into the dining space below. The triple windows below would be 2 fixed on the outer sides with the center operable.

However we also looked at a more traditional craftsman style and I went to the drawing board to try and make it not so text book. I admit, it is still a basic home with simple craftsman inspired details, but lets not forget efficient homes are not mean to be complex. They are meant to be fairly simple to keep the details simple. This sort of a home lends itself to that. We also feel, in the area, it is more fitting then the other designs we have looked at.

By playing with the color scheme, I was able to "modernize" the typical green and brown inspired craftsman homes. I am proposing using 2 tone blue-gray siding and white trim. However I am using a charcoal colored fascia, soffit, and gutters, as well as paint color matched decorative post gable details.

It uses a simple truss roof with hipped sides. The rear is a simple slope with no other detailing for easy construction and cost savings. The eyebrow set of 3 windows is functional casting additional light into the dining space below. The triple windows below would be 2 fixed on the outer sides with the center operable.

Saturday, October 1, 2011

SUN STUDIES

This section demonstrates how the sun will enter the house. The windows were sized many to allow maximum heat gain during the winter and shade the glass completely during the summer to reduce heat gains.

The sun is lowest in the sky on December 21st (about 25 degrees) and highest on June 21st (about 72 degrees). To allows maximum full glass winter gains, there needs to be a compromise in the overhang length in regards to the summer sun angles. 4 degrees offset seems to make about the most sense. This allows approximately 1 full month of sun on the glass in the winter (4 degrees above the winter solstice = about 29 degrees) and then 4 degrees below the summer solstice makes for approximately 68 degrees. This allows for 1 full month of shading on the glass during the summer. Using these angles, I am able to size my overhangs and heights of the windows to find the ideal placements for the windows.

To increase the heat gains through the glass, glass with the highest SHGC (solar heat gain coefficient) values will be selected. Typically, however, glass with high SHGC typically will not meat Energy Star ratings. This is where I think Energy Star makes little sense, as correctly sized windows with high SHGC on the south in our heated climate will perform far better then a typical dual pane, lower u window. However if triple pane windows are selected, they can be "tuned" by using hardcoat LowE coatings on several of the glass faces. Typically, hardcoats will produce the maximum heat gains, while softcoats result in the lowest. Most windows will be softcoat as standard as they are ideal for achieving the lowest u value as possible, which Energy Star wants.

Window companies such as Inline and Fibertec windows (as well as many others) allows you to 'tune' the glass and specify the coatings for each surface, for each window.

Using Inline thermal performance values, 2 options for the south would be a dual pane or a triple pane option.

Fixed windows

Dual pane numbers: SHGC= .56, U= .30

Triple pane numbers: SHGC= .44, U= .19

Obviously the dual pane option gives a higher SHG value, however the triple pane does also come with a much lower u value. A comparison between the estimated heat gain difference (of .12 SHG) and heat loss (u .11) will have to be compared to the price difference to see if the triple pane option makes sense on the south side.

Comparitively, similar windows with softcoats are:

Fixed windows

Dual pane numbers: SHGC= .33, U= .26

Triple pane numbers: SHGC= .28, U= .17

What does all of this add up to? Well, it is estimated that the south glazing and high SHGC will supply approximately 28% of the required heating for the entire house during the winter. If the house were designed to be more passive solar utilizing storage mass, the heat the sun would provide would increase to over 50% of the required heat during the winter...all for free.

Front Elevation

South Elevation

Here is an early view of the front. It faces south, and the window placement and roofs are all sized to utilize the free heat from the sun during the winter. The large triple window is in the dining room allowing that area to be flooded with light and warmth to radiate into the rest of the open spaces. The clearstory windows will allow light and sun rays to filter in from above and project further into the space warming the air. And of course...there is the 8' front door.

Here is an early view of the front. It faces south, and the window placement and roofs are all sized to utilize the free heat from the sun during the winter. The large triple window is in the dining room allowing that area to be flooded with light and warmth to radiate into the rest of the open spaces. The clearstory windows will allow light and sun rays to filter in from above and project further into the space warming the air. And of course...there is the 8' front door.

The Floor Plans

And here they are....as of October 1st, 2011....the 'current' floor plans. I say the date and current as they have seemed to change nearly daily (at least according to Shannon) and that has not been too far from the truth. But I think we are (ok, me) finally settling in on this plan. We have explored dozens of different arrangements, 2 story options, craftsman, etc. We think the single story with a finished, walkout basement will be the best option to not only build, but for a future growing family.

The Main Level:

A tour through the plan

A shop space is off of the garage for my tools and wood working. This space will be wood framed and open below as you will see on the basement plan. I will then apply a 2" concrete topping over the wood framing to create a smooth level surface flush with the poured garage slab.

You enter from the garage into the Mud room which features a hand wash/cleaning sink, some coat storage, and cubbies above and below a bench/sitting space.

Moving throw a sliding door (to eliminate a door swing and have the ability to leave the mud room open from the kitchen) you enter the kitchen. The kitchen is laid out to utilize various tasks found in the kitchen without overlapping/being in the way of someone else. The sink wall is upper cabinet free and 3 windows to view out over the deck and the backyard. A flat, sinkless free 8'x3' island will be used for many things.

The kitchen opens up to the Family room and views into the Dining room. The Family room, Dining room, and Entry are all in a taller section with ceiling heights at 14' (rest of the house is 9'). The Family room features a 5' wide stone fireplace (electric) that will go from floor to ceiling with a simple mantel .

The Dining room is nothing special, just a room that can comfortably seat 8 people. It is open to the Family room and Entry.

Moving down the hall the first bedroom is on your right with the laundry room to the left. I placed the laundry room in close proximity to the bedrooms and bathrooms, as well as the stairs for the downstairs bedrooms to keep hauling baskets of laundry to a minimum.

Next comes a simple bathroom at the end of the hall to the right, nothing special here. To your left you enter into the Master bedroom with the walk-in closet to the right. To the left is a recessed "makeup" station for Shannon so she can sit there and do her thing for 3 hours....

Heading into the Master bath, I have arranged it to have a "wetroom". The shower and soaker tub are surrounded completely by tiled walls, floors and glass. This allows all the water to be in one place. Step out of the tub and your are on a tile floor with a drain. Turn off the shower and you have plenty of space to stay there and dry off. Split vanities lead into a toilet closet.

Basement Plan

The stairs dump you out into an open area where a pool table will sit. To the right is a door that will lead out to the backyard onto a future patio space. The TV space will be our movie and my gaming area. The plan is to have a ceiling mounted projector and projection screen within the floor structure space.

The Office/Extra is just that...office space and auxiliary space, workout room, storage, etc.

Heading down the hall you pass the utility room (it will have a lot of space due to no furnace) and a bathroom at the end of the hall. Two identical bedrooms finish off the basement living space.

Under the shop space above is an unfinished space with a manual garage door where we will keep our lawn mower and outdoor related tools. Since the site slopes, it is actually cheaper to make this room instead of back filling and raising the grade for the slab above. Plus it will be great to keep the "dirty" tools and lawn equipment out of the garage space.

The Main Level:

A tour through the plan

A shop space is off of the garage for my tools and wood working. This space will be wood framed and open below as you will see on the basement plan. I will then apply a 2" concrete topping over the wood framing to create a smooth level surface flush with the poured garage slab.

You enter from the garage into the Mud room which features a hand wash/cleaning sink, some coat storage, and cubbies above and below a bench/sitting space.

Moving throw a sliding door (to eliminate a door swing and have the ability to leave the mud room open from the kitchen) you enter the kitchen. The kitchen is laid out to utilize various tasks found in the kitchen without overlapping/being in the way of someone else. The sink wall is upper cabinet free and 3 windows to view out over the deck and the backyard. A flat, sinkless free 8'x3' island will be used for many things.

The kitchen opens up to the Family room and views into the Dining room. The Family room, Dining room, and Entry are all in a taller section with ceiling heights at 14' (rest of the house is 9'). The Family room features a 5' wide stone fireplace (electric) that will go from floor to ceiling with a simple mantel .

The Dining room is nothing special, just a room that can comfortably seat 8 people. It is open to the Family room and Entry.

Moving down the hall the first bedroom is on your right with the laundry room to the left. I placed the laundry room in close proximity to the bedrooms and bathrooms, as well as the stairs for the downstairs bedrooms to keep hauling baskets of laundry to a minimum.

Next comes a simple bathroom at the end of the hall to the right, nothing special here. To your left you enter into the Master bedroom with the walk-in closet to the right. To the left is a recessed "makeup" station for Shannon so she can sit there and do her thing for 3 hours....

Heading into the Master bath, I have arranged it to have a "wetroom". The shower and soaker tub are surrounded completely by tiled walls, floors and glass. This allows all the water to be in one place. Step out of the tub and your are on a tile floor with a drain. Turn off the shower and you have plenty of space to stay there and dry off. Split vanities lead into a toilet closet.

Basement Plan

The stairs dump you out into an open area where a pool table will sit. To the right is a door that will lead out to the backyard onto a future patio space. The TV space will be our movie and my gaming area. The plan is to have a ceiling mounted projector and projection screen within the floor structure space.

The Office/Extra is just that...office space and auxiliary space, workout room, storage, etc.

Heading down the hall you pass the utility room (it will have a lot of space due to no furnace) and a bathroom at the end of the hall. Two identical bedrooms finish off the basement living space.

Under the shop space above is an unfinished space with a manual garage door where we will keep our lawn mower and outdoor related tools. Since the site slopes, it is actually cheaper to make this room instead of back filling and raising the grade for the slab above. Plus it will be great to keep the "dirty" tools and lawn equipment out of the garage space.

Saturday, August 20, 2011

The wishlist, part one (meaning it will keep on growing!!)

Shannon and I make a pretty good team. We are rarely disagreeing on things to go in the house. Minor things here and there, but nothing big yet at all. Our wish lists are pretty easy, and neither one of us require an extravagant house. Just comfy with a few small splurges here and there.

So here is the start of our wish lists:

Shannon- Hers is pretty simple.

-8' main entry door with a big canopy roof over it. "grand entry" I suppose she would call it.

-sliding glass doors with blinds in the glass going out to the deck. She likes the privacy of blinds, but hates externally mounted blinds on doors. Thus, this is the option. Few brands make a good one, so we are limited to Eagle or Pella Designer series basically. Both can be had from my reps, so no big deal :)

-Master bath with a soaker tub- while I do not really think this is needed, I suppose it would be pretty dumb to build a new house and not have both a shower and a tub in the master bath.

-Separate "formal" dining room. I would be fine if it were an open space with the kitchen, as it is more efficient use of square footage...but, I can see her point and will be a nice feature for family gatherings.

Jesse:

-Super insulated, super efficient house- pretty self explanatory. I have done pushing 2 years of research on energy efficient construction, costs, life costs, and various other areas of home efficiency. It is quite obvious going just a few steps more in the building process (and in most cases at minimal extra cost in the whole scheme of things) can make a HUGE difference on your utilities bills, energy consumption, and comfort within the home. More on all of this fun fun stuff later.

-geothermal heating and cooling- it "feels" right given my green attempts, my professional and practicing what I attempt to preach. There are many other benefits as well, more on that later.

-in wall speakers- this is sort of both of our areas, but me especially. Anyone who knows me (and us) know how important music is to listen and play. An integrated home audio system is clean, simple, and will be a nice "splurge".

-movie/gaming/pool table area- walkout basement will be the location for this. I want a pool table, and then a nice large family area to gather for movies. Complete with a ceiling mounted projector and screen!

-large shower in the master- I hate cramped small showers, so I want a large shower in our bathroom. Shan will agree here as well.

-a nice shop space that can be separate from the garage and be devoted to drum building and other projects.

-soap stone counters in the kitchen- this I may or may not win. Why? because it looks so sleek and modern and very "natural".

-some sort of different or "wow" design to the house mass- hey, its what I do!

Combined wish lists- what we both really want-

-large kitchen with an open feel and large island with seating. Most cases people congregate in the kitchen, so we are taking all of the "zones" into consideration. More on this with kitchen layout.

-main living room with large fireplace area. Just to give it a nice, cozy relaxed atmosphere and a separate space for girls and boys (boys being downstairs :) )

-min. 2 car garage- self explanatory

-outdoor patio/fire pit/entertaining area off the basement.

-bamboo wood floors- they are green, very durable, a good price, and look sleak and modern.

-Main floor laundry

-mud room- I would be fine if the mudroom and laundry shared the same space, however Shannon would like them separate, so as my dad always says..."happy wife, happy life"....

This list will be a living list I am sure, growing as we progress. But the main items above are for sure coordinated into the final design.

So here is the start of our wish lists:

Shannon- Hers is pretty simple.

-8' main entry door with a big canopy roof over it. "grand entry" I suppose she would call it.

-sliding glass doors with blinds in the glass going out to the deck. She likes the privacy of blinds, but hates externally mounted blinds on doors. Thus, this is the option. Few brands make a good one, so we are limited to Eagle or Pella Designer series basically. Both can be had from my reps, so no big deal :)

-Master bath with a soaker tub- while I do not really think this is needed, I suppose it would be pretty dumb to build a new house and not have both a shower and a tub in the master bath.

-Separate "formal" dining room. I would be fine if it were an open space with the kitchen, as it is more efficient use of square footage...but, I can see her point and will be a nice feature for family gatherings.

Jesse:

-Super insulated, super efficient house- pretty self explanatory. I have done pushing 2 years of research on energy efficient construction, costs, life costs, and various other areas of home efficiency. It is quite obvious going just a few steps more in the building process (and in most cases at minimal extra cost in the whole scheme of things) can make a HUGE difference on your utilities bills, energy consumption, and comfort within the home. More on all of this fun fun stuff later.

-geothermal heating and cooling- it "feels" right given my green attempts, my professional and practicing what I attempt to preach. There are many other benefits as well, more on that later.

-in wall speakers- this is sort of both of our areas, but me especially. Anyone who knows me (and us) know how important music is to listen and play. An integrated home audio system is clean, simple, and will be a nice "splurge".

-movie/gaming/pool table area- walkout basement will be the location for this. I want a pool table, and then a nice large family area to gather for movies. Complete with a ceiling mounted projector and screen!

-large shower in the master- I hate cramped small showers, so I want a large shower in our bathroom. Shan will agree here as well.

-a nice shop space that can be separate from the garage and be devoted to drum building and other projects.

-soap stone counters in the kitchen- this I may or may not win. Why? because it looks so sleek and modern and very "natural".

-some sort of different or "wow" design to the house mass- hey, its what I do!

Combined wish lists- what we both really want-

-large kitchen with an open feel and large island with seating. Most cases people congregate in the kitchen, so we are taking all of the "zones" into consideration. More on this with kitchen layout.

-main living room with large fireplace area. Just to give it a nice, cozy relaxed atmosphere and a separate space for girls and boys (boys being downstairs :) )

-min. 2 car garage- self explanatory

-outdoor patio/fire pit/entertaining area off the basement.

-bamboo wood floors- they are green, very durable, a good price, and look sleak and modern.

-Main floor laundry

-mud room- I would be fine if the mudroom and laundry shared the same space, however Shannon would like them separate, so as my dad always says..."happy wife, happy life"....

This list will be a living list I am sure, growing as we progress. But the main items above are for sure coordinated into the final design.

Tuesday, August 16, 2011

The hopeful site

Located just north west of Denver, IA sits a nice development called Rose Hills. A member of our church owns the development, and we have discussed this lot location shown above for the site. It is an undeveloped portion of the site, however the plan is to acquire approximately one acre. The house would have a southern facing front elevation on relatively flat terrain.

The site then slopes down to the north allowing a walkout basement opening up to a backdrop of nothing but mother nature. Hitting the tree line, it drops rather rapidly to a small revean with an often dry stream at the bottom. With the clearing to the south, this allows the house to be placed to take advantage of winter solar heat gains. With the thicker trees to the north (a good portion of them being evergreen), this should also allow for decent north prevailing wind blockage as well.

Here are some additional photos of the site.

The hopeful dream

After well over a year in the making, we THINK we are solidifying the plan and construction type. As I work through the more "final" details of the plan, I can get some loaded up here for everyone to see. More details will come later as plans and designs are uploaded. I will be able to get into the nitty gritty of the project and reasons behind the design and selections later.

Subscribe to:

Posts (Atom)